Product Description

Robustness, reliability and accuracy of hydraulic Universal Testing Machine

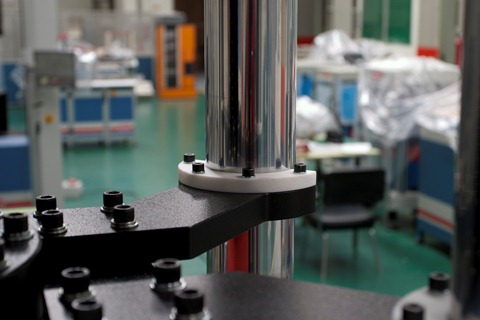

The IBMT4 series is a testing machine solution with a structural frame with 4 columns of high strength steel, which provide the necessary stiffness to meet the highest standards of quality and accuracy at high loads of materials testing.

Advantages for Materials Testing

- 100% automatic operation, Hydraulic cylinder motion is performed by a high quality servo valve, ensuring better precision in the test.

- Hydraulic gripping heads for maximum clamping assurance.

- Total adaptation to customer needs.

- Configurable dimensions preserving maximum stiffness criteria.

- Can be equipped with several interchangeable load cells.

- Gripping Head guided by 4 columns, ensuring optimum performance against lateral loads and ensuring conservation of axiality.

- Allows control testing speed by load, displacement and strain.

More information

Compression plates, designed for direct connection to machine gripping heads.

The IBMT4 testing machines series of IBERTEST have several kind of testing heads as well as other differents testing devices, that allows to do different types of test:

- Tensile test according to ISO 6892, ISO 1608, EN 10002-1 and ASTM E23

- Compression test ASTM D695

- Bending test according to ASTM E290

- Folding test

- Shearing test

- Fatigue test (at low frequencies)

- Others as the test according to NADCAP GE-S400, CREEP, ASTM E 139

All these tests realized in many different materials such as:

- Steel

- Aluminum

- Other metals

- Composites

- Wood

- Cement

- Concrete

Bending and folding device designed for direct connection to machine gripping heads.

In our metrology laboratory where we have profile projector, hardness testers, roughness, 3D Coordinate measuring machines, etc.. are verified all key components of IBERTEST testing machines.

Our testing machines not only ensure its quality through quality control of each component, the machine is verified in a global way and functionality, being calibrated by our official calibration and certification laboratory, accredited by ENAC (ILAC member) which issues a calibration certificate valid internationally according to ISO 7500-1.